-

Products

- Silicone Rubber Molding

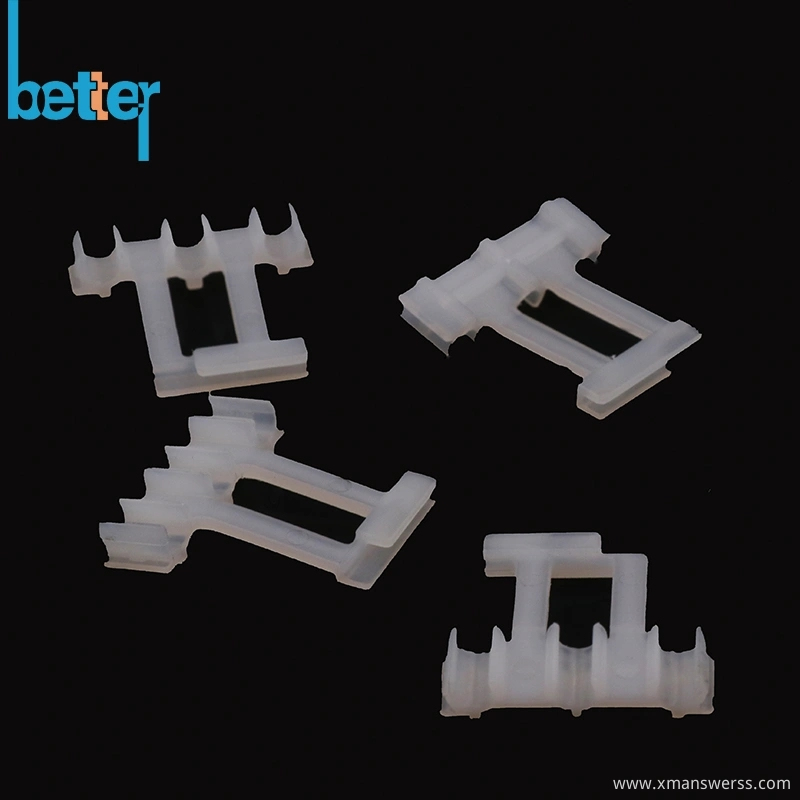

- Plastic Injection Molding

- Self Adhesive Rubber Pad and Mat

- LSR Molding

- Medical LSR

- Rubber Suction Cup

- Silicone Houseware

- Rubber Bellows & Dust Cover

- Rubber Grommets

- Medical Silicone >

- Rubber Bumper

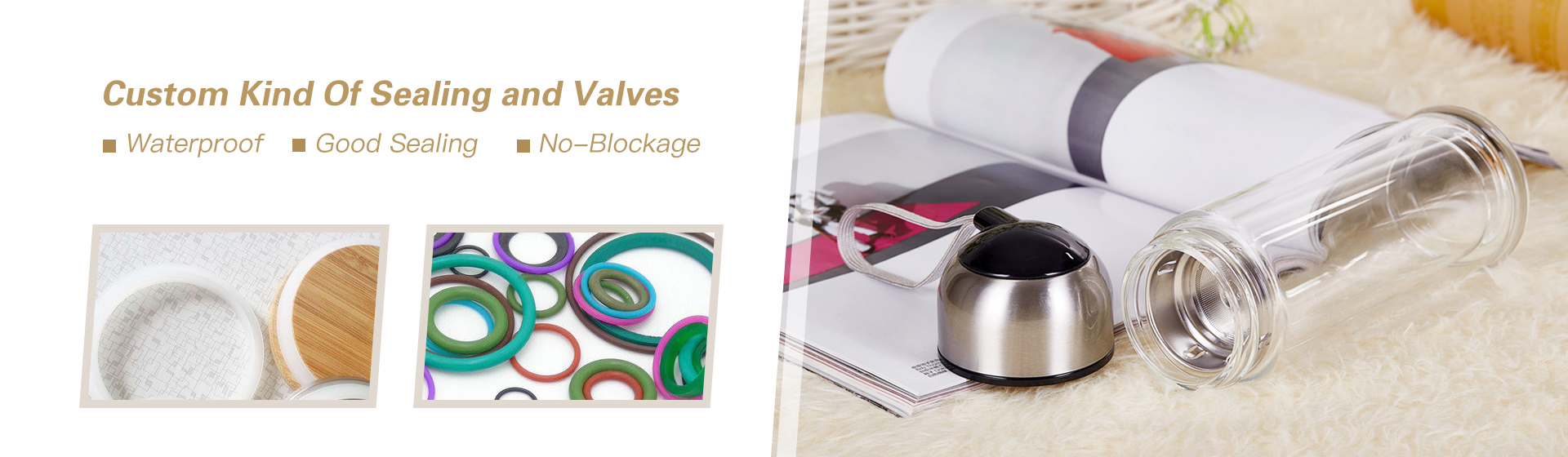

- Silicone Rubber Seal >

- Silicone Promotional Items

- Rubber Bushing

- Rubber Bellows and Tubing

- Rubber Grommet

- Rubber Keypads and Keyboard

- Medical Silicone products

- Medical Product

- Rubber Sleeves

- Rubber Plug and Silicone Stopper

- Silicone Baby Products

- Rubber Stopper & Plug

- Silicone Cover and Rubber Sleeves

- Silicone Keypads and Rubber Keyboard

- Silicone Promotion Gifts >

- LSR Injection Molding and Silicone Injection Molding

- About Us

- News

- Video

- Contact

- Send Inquiry

- Download

- Home